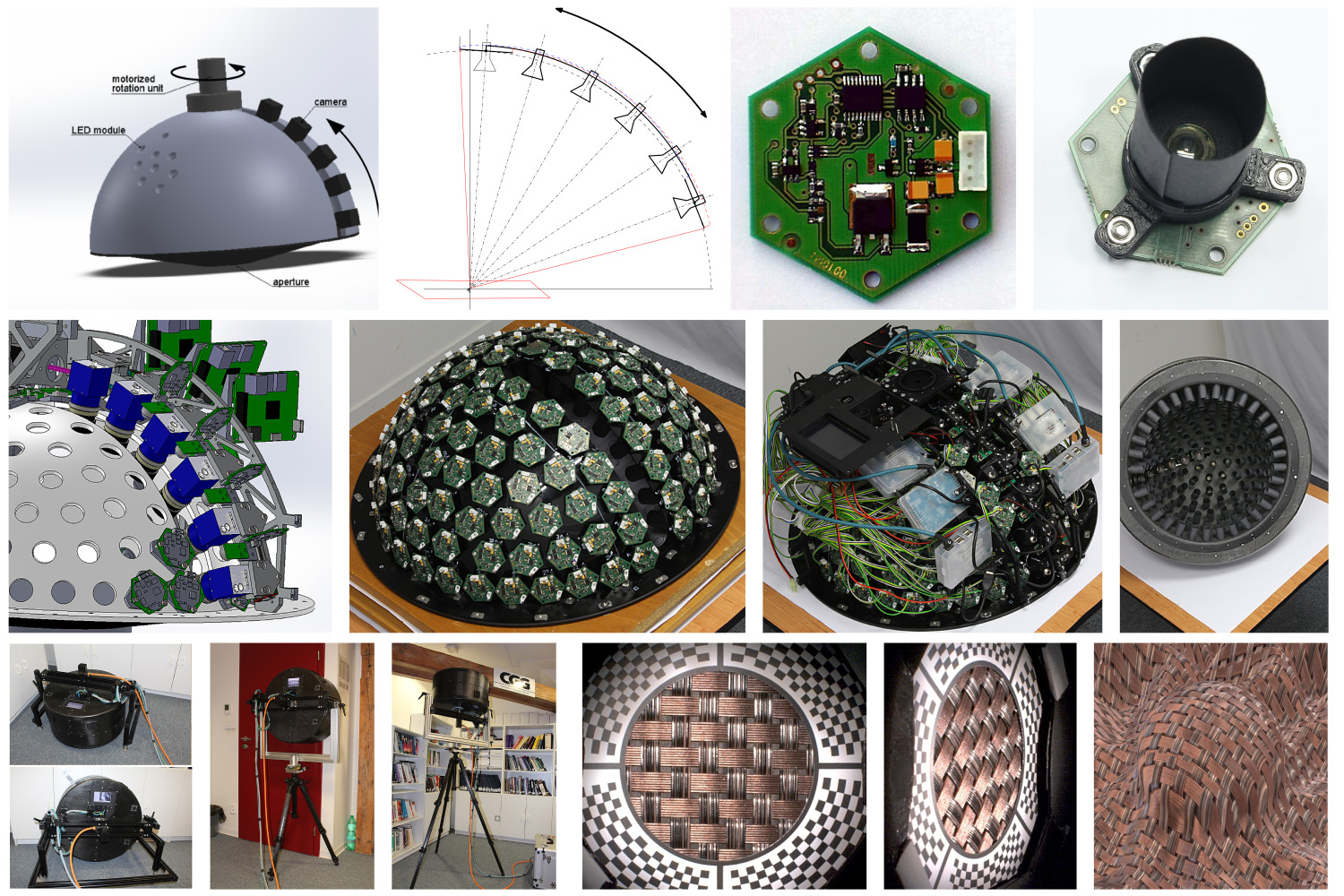

We have constructed a special measurement device called Lightdrum

The research team led by Associate Professor Vlastimil Havran at the Department of Computer Graphics and Interaction of the Faculty of Electrical Engineering, Czech Technical University, constructed a special measurement device called Lightdrum. It can very effectively measure the surface appearance of real objects for subsequent reproduction in computer programs. This significantly improves the quality of computer visualizations and virtual reality, in which objects surfaces are now generally rendered too simplified and unrealistic. The advantage of the Lightdrum against other stationary laboratory devices is, in addition to accuracy and speed of measurement, its compactness and ease of portability for measurement on-site.

Virtual Reality (VR) and design by designers and architects in the form of pictures and videos often do not work in real life, and one has to spend a lot of imagination and imagination to estimate how, for example, a dream car or house will actually look like. Most computer programs use so-called 2D texturing for rendering surfaces, when the detailed but only one photograph of the surface is stretched and copied across the entire surface of the object. In this way, visualizations that do not respond to the illumination and the view direction of the shot as well as the actual surface of the material are created, and the result seems unrealistic. Such materials are, for example, leathers, fabrics, wood or walls. If a real appearance of these surfaces under various lighting conditions was required in the past, it was necessary to take a sample of the material to a large instrument in the laboratory, which then gained the necessary data within hours and days. Because such a procedure is often inadequate or totally impossible, the team of the Havrana has developed a new device for the appearance of surfaces on and outside the lab.

A device called Lightdrum was created at the Department of Computer Graphics and Interaction of the Faculty of Electrical Engineering in close cooperation with specialists from the Faculty of Mechanical Engineering at CTU. It is a mobile and extremely efficient measuring device that can be attached to almost any surface with the aid of holding frames and then accurately measure how the surface will look at any lighting. The device looks like a cylinder, inside of which 6 HDR cameras are used, and 139 LED modules provide illumination of the measured sample. The servomotor rotates the device around its axis, and the cameras inside can also move along meridian. Unlike its bulky and non-mobile laboratory predecessors, Lightdrum has a diameter of 600 mm and a length of 400 mm. Measurement of the 35 x 35 mm sample surface, which consists of taking a set of photographs, is also much faster than in the past. The whole process produces 16,680 HDR photos in just 17 minutes. Each photo has a different illumination direction from 139 LED modules and the camera direction to the surface. The package of HDR captured photos takes 40 GB. It is then processed on a computer in reasonable size and format and then usable for new versions of software tools.

In the future, the invention can be used wherever a realistic virtual presentation of the design is required - for example, in the automotive industry, architecture, fashion design and general industrial design. It can save a lot of time or frustration, which the customer often experiences, when the real impression does not match the visualization when ordering.

Lightdrum can also be used in the film industry, digitization of cultural heritage and computer games. Game developers use advanced technologies to work in real-time photorealistic environments. With the digitized look produced by this invention, they will be able to shift the realism of games and simulators to a higher level. Likewise, virtual reality developers and retailers in a number of other industries can benefit from this invention.